Lamella’s

The Lamella blocks are used in the industry as classifiers or separators. Industrial plant waste and sewage are purified and re-used with the help of flocculent to precipitate the sedimentable particles in a continuous process/plant.

In wastewater treatment the four main steps are collection and homogenization of effluent, pH adjustment, clarification, and sludge dewatering. Conventional clarification equipment requires a much larger surface footprint in order to match the solids removal capacity of a lamella clarifier

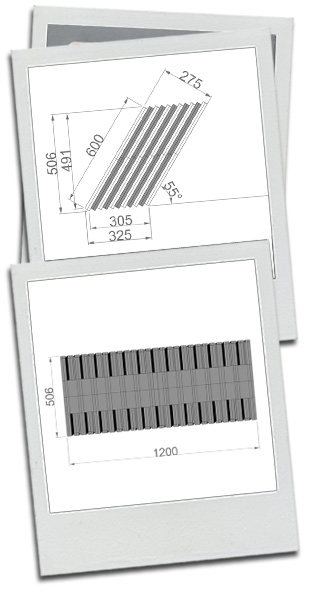

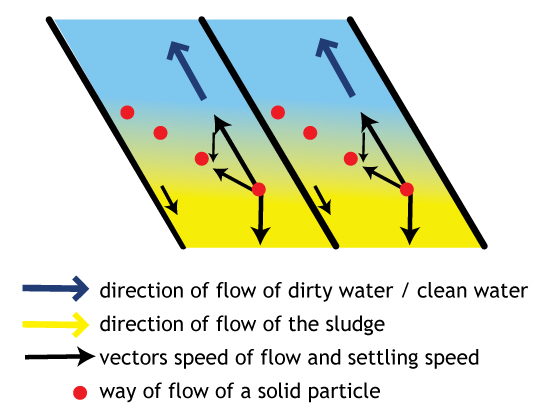

The Lamella block is a honeycomb at a 55° to 60° incline structure. The effluent (industrial plant waste or sewage) is usually mixed with a polymer flocculent and enters the lamella blocks from the bottom.

Sketch 1: Flow of effluent and precipitation.

As the liquid flows upward, the solids settle on the incline and slides to the bottom as it is building up. The clarified liquid leaves the lamella honeycomb at the top, ready for re-use.

Characteristics:

- Made from UV stabilised Rigid PVC

- High surface to volume ratio

- Long lasting

- Resistant to acids and alkalis

- Flammability - self extinguishing

- Removes solids in water & sewage

- Improves sedimentation in water & waste water treatment plants

Trickling Filters/Bio-filters

Characteristics:

- Made from UV stabilised Rigid PVC

- High surface to volume ratio

- Long lasting

- Resistant to acids and alkalis

- Flammability - self extinguishing

- Removes solids in water & sewage

- Improves sedimentation in water & waste water treatment plants

| Product: | Lamella’s |

|---|---|

| Application: | Water treatment, Gravel and sand industry, Recycling industry, Glass / Ceramics / natural stone, Chemical industry, Energy industry / cooling water, tunnelling / construction sites, Food industry, Waste, Landfill / street-cleaning, Heavy metal precipitation /mining industry |

| Dimensions: | 1200 x 325 x 506 |

| Colour: | Black PVC |

| Special notes: | Supplied in block or sheet form |

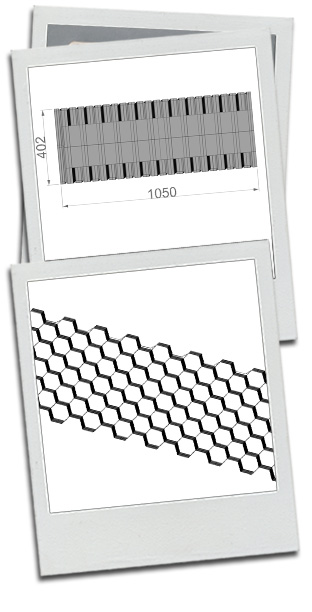

| Product: | Trickling Filters/Bio-filters |

|---|---|

| Application: | Roughing or pretreatment,Complete secondary treatment, Upgrade of rock trickling filter Nitrification/Denitrification |

| Dimensions: | Various sizes available |

| Colour & Material Type: | Black PVC/Grey ABS for High Temperature Applications |

| Special notes: | Supplied in block or sheet form |